Rigid, Stable, Accurate

Rigid, Stable, Accurate

RUGGEDLY CONSTRUCTED THROUGHOUT TO PROVIDE LIFETIME ACCURACY YEAR AFTER YEAR

- The major structural parts are manufactured form high quality Meehanite cast iron (GB 300),

tempered for stress relief with hardness over 190HB. - 25mm Roller type linear ways on X, Y, Z axis increased stability.

- X, Y, Z axis are transmitted with class C3, Ø28mm ball screws.

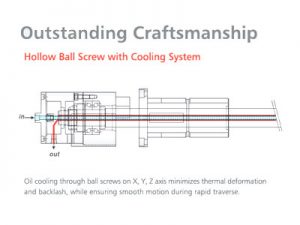

HOLLOW BALL SCREW WITH COOLING SYSTEM

Oil cooling through ball screws on X, Y, Z axis minimizes thermal deformation and backlash,

while ensuring smooth motion during rapid traverse.

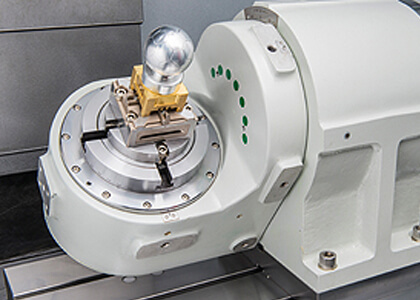

COOLING SYSTEM TO SPINDLE

The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life.

It also provides high efficiency machining and high accuracy.