Features

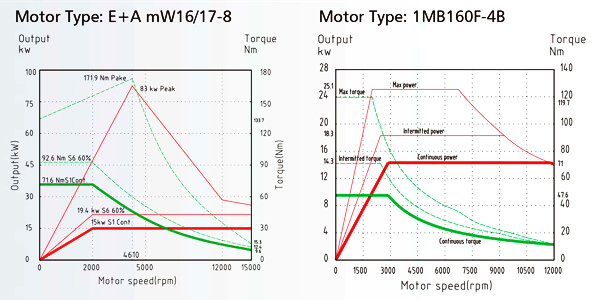

Hi-Speed, Hi-Power, Hi-Torque, Built-in Spindle 15000 rpm, swivels ±120°

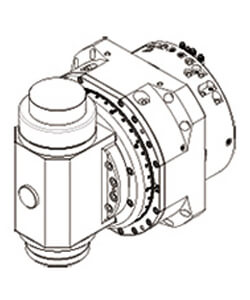

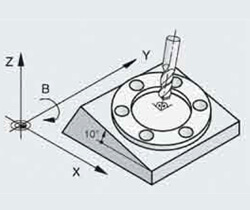

UNIQUE B-AXIS DESIGN(OPTION)

The transmission mechanism of B axis for BX-series is innovated from dual worm wheel/shaft to direct drive.

In addition to the smooth and powerful torque, the direct driving system features higher rotation sped, high servo response, zero backlash,

and outstanding dynamic accuracy for the optimum workpiece surface finish. The external cooling system efficiently minimizes the structural thermo deformation and accuracy deflection, more over, the output torque is upheld since the temperature is constantly kept in low and stable level.

The rear end of B axis shaft is fitted with and angular position coder to boost positioning accuracy of B axis.

The application of direct drive motor in B axis increases the overall accuracy as well as machining efficiency of the machine.

Pinnacle BX is the best cost-effective manufacturing investment of 5-axis simultaneously controlled machining centers,

it brings positive and instant results by improving machining accuracy and reducing cutting time.

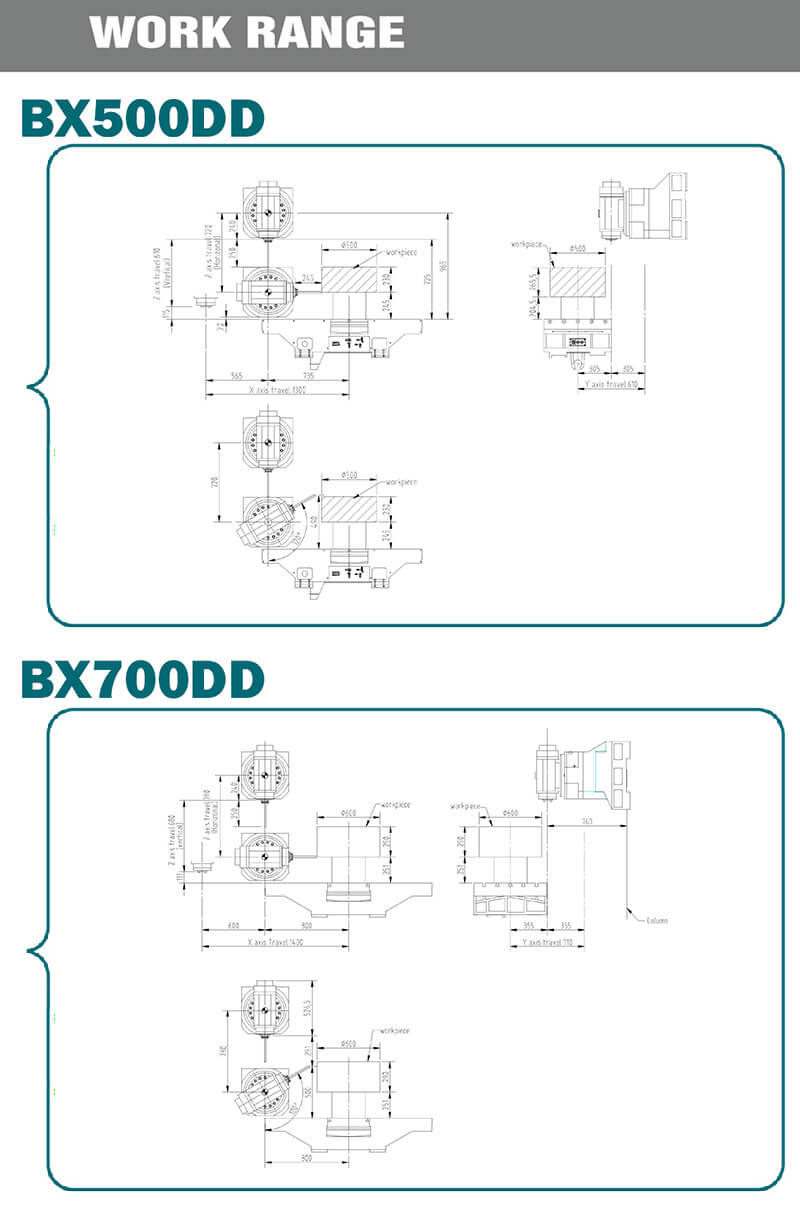

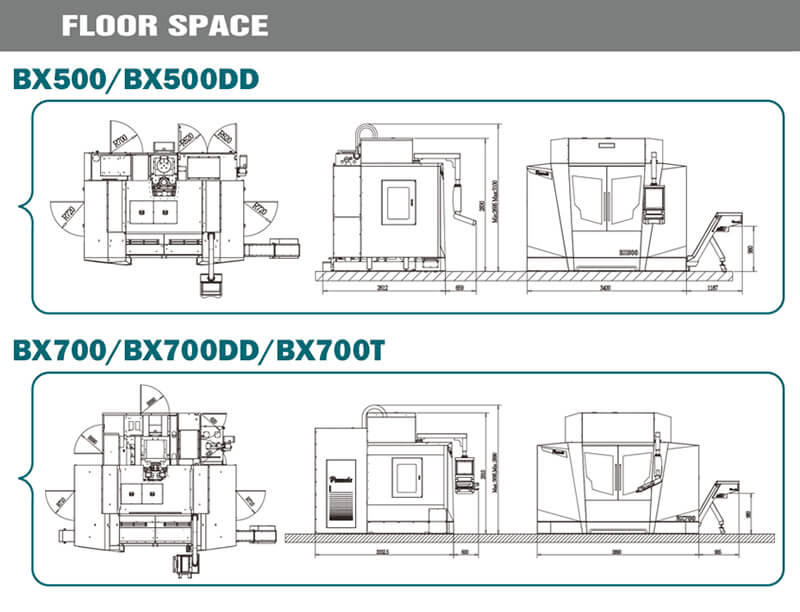

BX700 / BX500 is high speed, high accuracy with HEIDENHAIN TNC640 5-axis simultaneously controlled machining center.

Equips 15000rpm built-in spindle, B-axis swivel head ±120°, and C-axis Ø630mm rotary table (Built-in DD C-axis) to optimize machining space

and allows complex workpieces to be finished in just one setup and reduces cycle time.

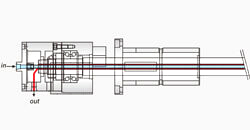

PNEUMATIC BALANCE SYSTEM

The Z-axis is pneumatic counter-balanced via high response pneumatic cylinders.

Plus an air reservoir tank to boost the balancing performance, ensuring fast and stable Z-axis movement, giving high surface finish.

COOLING SYSTEM TO SPINDLE

The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life.

It also provides high efficiency machining and high accuracy.

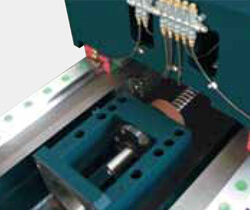

LINEAR ROLLER GUIDEWAY

X/Y/Z axes adopt roller guideways for optimum rigidity and speed.

6 rolling shoes on X/Z axes minimize damping effect.

RIGID MACHINE BASE AND SADDLE

Drive motors direct coupled with pretensioned and oversized ball screws to ensure cutting quality.

TILTING THE WORKING PLANE

Use tilting the working plane. With Cycle 19 with swivel heads or tilting tables.

You program the operation as usual in the working plane, for example in X/Y.

The machine runs the program in a plane that has been tilted by one or more rotary axes with respect to the main plane.

TCPM FUNCTION (TOOL CENTER POINT MANAGEMENT)

In five-axis operations, TCPM function to move the tool reliably on the contour and ensure that the work surface is not damaged.

Maintain the position of the tool tip when positioning with tilted axes.

With the aid of the TCPM function, the iTNC 530 automatically corrects the tool path for the machine geometry

and the tool length as well as compensates the tool radius in three dimensions.

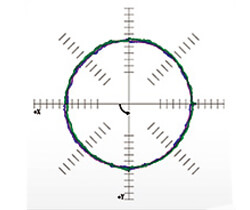

KINEMATICE OPT. (OPTION)

KinematiceOpt. is an important component to help you meet these high requirements:

With a HEIDENHAIN touch probe inserted, a 3-D touch probe cycle measures your machine’s rotary axes fully automatically.

The results of measurement are the same, regardless of whether the axis is a rotary table, a tilting table or a swivel head.